Basic boiler checks can save you time and money, so are worth carrying out if you think you are dealing with a simple issue.

- Which boiler checks can & can't be done yourself?

- 10 boiler checks you can do yourself

- Bleed your radiators

- Check your boiler pressure

- Inspect the Electrics

- Check the Diverter Valve

- Check Your Boiler Thermostat and Timer

- Check Your Pilot Light

- Check the Gas Supply

- Check Radiator Valves

- Check the Condensate Pipe

While most boiler work must be undertaken by a professional, that’s for good reason.

After all, many boiler problems are complex and potentially dangerous, unless performed by a competent Gas Safe Registered engineer.

However, the good news is that some boiler jobs and basic boiler checks can be simple DIY tasks.

But which ones in particular?

Let’s dive in!

Which boiler checks can & can't be done yourself?

In all honesty, there isn’t much that you can do DIY (at least in the scheme of all possible boiler checks/tasks).

However, if it simply involves inspecting your boiler or heating system from the outside, this will generally fall under acceptable DIY work.

Moreover, certain other tasks are also possible without the help of a professional.

For instance, if your boiler pressure is too low, it will generally be fine to top up the boiler yourself.

However, if you find that the pressure of your boiler continues to drop, even after you top it up, this suggests there’s a leak, which would need to be fixed by a professional.

So, as you can see, it isn’t always straightforward.

But thankfully, we’ve compiled a list of ten checks that are easy and should tell you what you need to know there and then.

PS If you smell gas from your boiler this is an emergency and you should call the Emergency Gas number (0800 111 999) immediately.

10 boiler checks you can do yourself

Bleed your radiators

First and foremost, if your radiators aren’t working as they should be (e.g., their efficiency seems to have dropped quite fast or/and there are cold spots near the top of your radiators), they may just need to be bled.

Check out our comprehensive guide on bleeding your radiators (including video guidance).

But here is a simple overview...

This is the process of releasing air pockets from a radiator, which in turn, will make it easier for your heating system to do its job.

You can bleed your radiators through the following steps:

1. Turn off the heating and give your radiators sufficient time to cool down.

2. Place a towel beneath the bleed valve of the first radiator you want to bleed. Then position a jug atop the towel, again directly below the bleed valve. These hold the purpose of catching excess water.

3. Fit the bleed key into the radiator and gradually turn it anti-clockwise.

4. As air escapes, you’ll notice a hissing sound coming from your radiator. As soon as water begins to exit the bleed valve, it’s time to close it, by turning the bleed key clockwise and back to its original position. You may need to pay attention to how far you turn it in the first place, in order to turn the bleed key back to the position it started in.

5. Repeat the four steps described above with every radiator on your property.

6. Once you are satisfied, turn your heating back on. Now, evaluate each radiator and ensure that they are heating up the right way. If not, either you made an error with that specific radiator, or another issue is at play.

Check your boiler pressure

It’s possible that an issue with your boiler pressure is the cause of an issue with your boiler/heating system.

Therefore, it’s worth checking your boiler pressure by yourself before calling out a gas engineer.

Your boiler pressure should likely fall somewhere in the region of 1 bar to 1.5 bars.

However, you should confirm with the manufacturer’s guide what the ideal pressure range is for your particular appliance.

However, you should be aware that if you find your boiler pressure is too high that this must be dealt with by a professional.

But, if your boiler pressure is too low, you can fix this DIY. Combi boilers are especially prone to low boiler pressure.

While you can use the below steps, if you are in doubt, please check the manufacturer’s guide for the specifics of how to repressurise your boiler specifically.

You can top up a boiler with low pressure by taking the following steps:

1. Check the pressure gauge and confirm that your boiler pressure is low per the manufacturer’s guide.

2. Identify the filling loop (which will be toward the bottom of your boiler) and use it to repressurise your boiler.

3. Turn off your boiler.

4. Ensure the ends of the hoses are connected to the valves. This is necessary to prevent leaks.

5. By opening the valves, you will hopefully notice the sounds of your system being filled up by water. This is the part where your boiler is being topped up.

6. Keep a close eye on the pressure gauge. Close valves when the gauge hits 1.5 bars.

7. Turn your boiler back on.

If your boiler loses pressure again relatively soon after being repressurised, it means there’s likely a leak.

Either way, you will need to hire a professional if you find your boiler is repeatedly losing pressure.

Inspect the Electrics

If your boiler lacks power, it’s possible that an electrical fault is at play.

Thankfully, this tends to be an easy DIY fix.

But, when it comes to electrics, always proceed with caution and only undertake work that is suitable for a DIYer. If in doubt, hire a professional.

After all, electrocution can easily kill.

It may be the case that (if an electrical fault is to blame), the boiler’s fuse has blown. In this case, you can buy a new fuse as a replacement. Ensure you buy the right fuse for your boiler.

In order to make the fix, first, you must turn off the power at the mains before replacing the fuse per the manufacturer's instructions.

Once you are certain it is installed correctly and the job is complete, you can turn your power back on at the mains and see if your boiler comes back on.

It’s also possible that your boiler’s RCD switch has tripped. This is particularly likely if you’ve experienced a power outage recently.

Go to your fuse box and look for any switches that are turned off. Flick them back on and hopefully (if the fuse is not the issue), this will power your boiler back up.

You may be interested in Gas Engineer Allen Hart explaining the most common boiler problems and how you can resolve them in the video below:

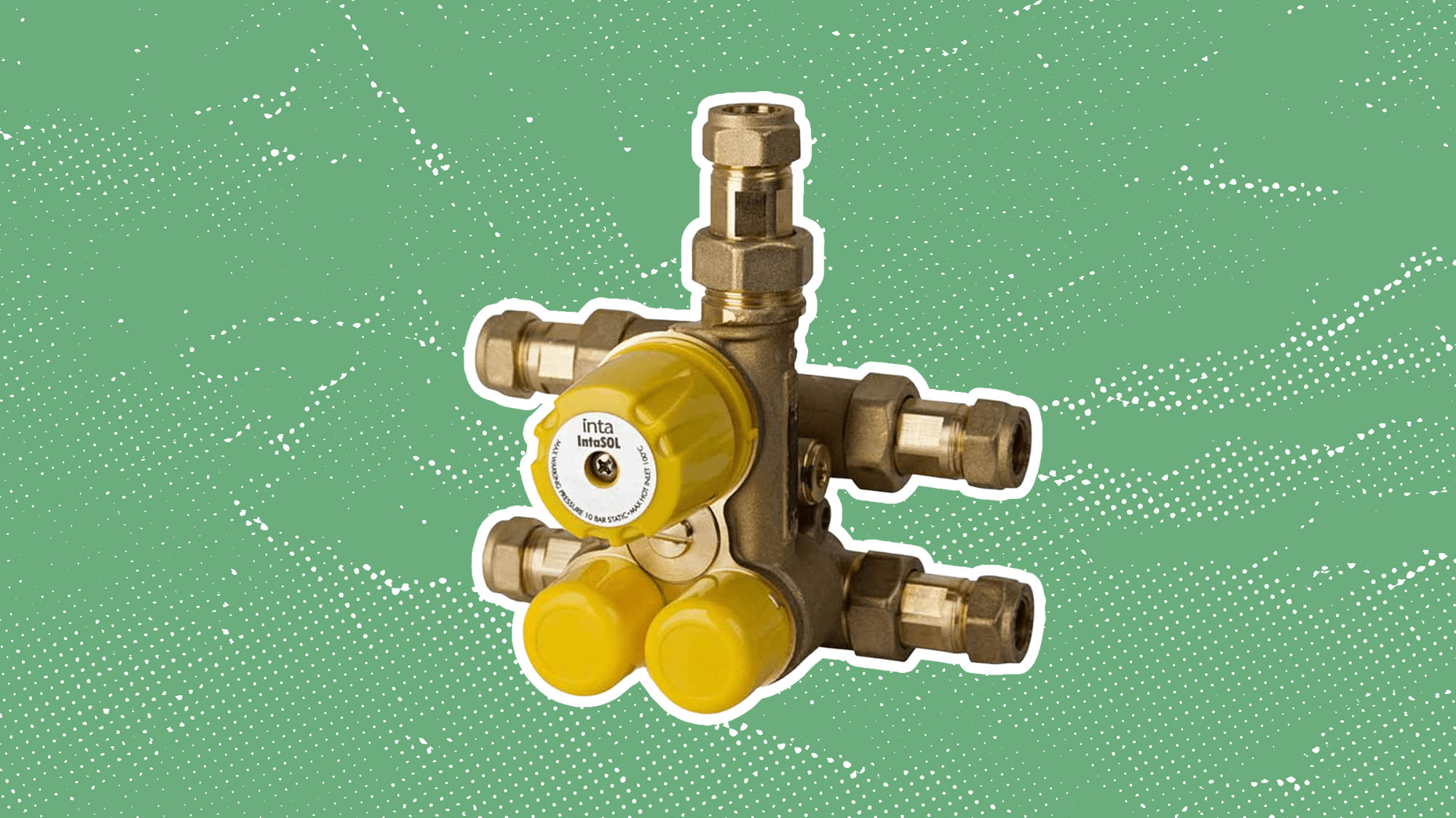

Check the Diverter Valve

Another potential DIY fix relates to a combi boiler with heating but no hot water.

If this accurately describes your boiler predicament, the issue may lie with your boiler’s diverter valve.

This is an electrical component designed to switch a combi boiler’s function from heating to hot water and vice versa.

If you’ve heating but no hot water, it may mean that your diverter valve is faulty or simply stuck in one position.

One way of increasing your confidence that the diverter valve is the culprit is that you find you must turn your central heating up to its maximum setting until you’ve any hot water at all.

While you cannot fix a faulty diverter valve DIY, the good news is that if you are confident, that it is the problem, you’ll be able to point a heating engineer in the right direction.

This would make their job easier and quicker and, therefore, hopefully, cheaper for you.

Check Your Boiler Thermostat and Timer

If your boiler isn’t firing up, it’s worth taking a look at your thermostat and timer.

Just as a boiler may have no power due to issues with your electrics, a boiler that simply won’t fire up may have an electrics problem to blame.

If your electrics recently tripped or you’ve experienced a power outage lately this may have accidentally reset the boiler thermostat and timer.

If they were reset, then your boiler may not be able to fire up at the times desired.

To solve this issue (if present), inspect the times on your boiler thermostats and timers.

If they are off, simply reprogram them per the manufacturer’s instructions.

Make sure your room thermostat has the right settings so that your boiler will heat your property at the right temperatures.

If you believe the issue is with your thermostat and timer but the above actions don’t help, make sure the batteries aren’t in need of replacing.

Check Your Pilot Light

If your boiler fails to ignite and you have an older version, you should check the pilot light.

If you find the pilot light is not lit, you can reignite it with the help of the manufacturer’s guide.

Alternatively, newer models do not have pilot lights.

So, if your boiler isn’t igniting, it’s worth pressing the deblocking button (again following the manufacturer’s instructions).

This will attempt to reignite your boiler’s burner.

However, if this doesn’t work, you’ll need to hire a professional to find out exactly what’s going on and get your boiler burner working again.

Check the Gas Supply

If you believe that your boiler is not receiving its gas supply, there are a few things you can do DIY.

You should attempt the following:

Inspect your boiler’s emergency control valve and ensure it’s open. If it’s closed, re-open it only if you are sure that it was not closed for an actual emergency (e.g., gas leak). If in doubt, hire a professional.

Check your gas stopcock and open if it required. You may even need to open the emergency control valve and gas stopcock.

If both the emergency control valve and gas stopcock are open but you have no gas supply, then the issue probably lies with your supplier. And, in this case, you’d need to contact your gas supplier to have the problem resolved.

Reset Button

Another thing worth checking if your boiler isn’t functioning as intended is whether it simply needs to be reset.

Yes, this sounds like a surprisingly easy explanation, but it could prove the answer.

Considering boilers have a whole host of safety devices, it’s possible that one (or several) of these devices have tripped.

If so, your boiler needs to be reset. Boilers tend to have their reset button at the front.

It shouldn’t be necessary to remove the access panel to find the reset button. If in doubt, take a look at the manufacturer’s guide.

While resetting your boiler may do nothing to solve your problems, if you think it could help, there’s no harm in trying.

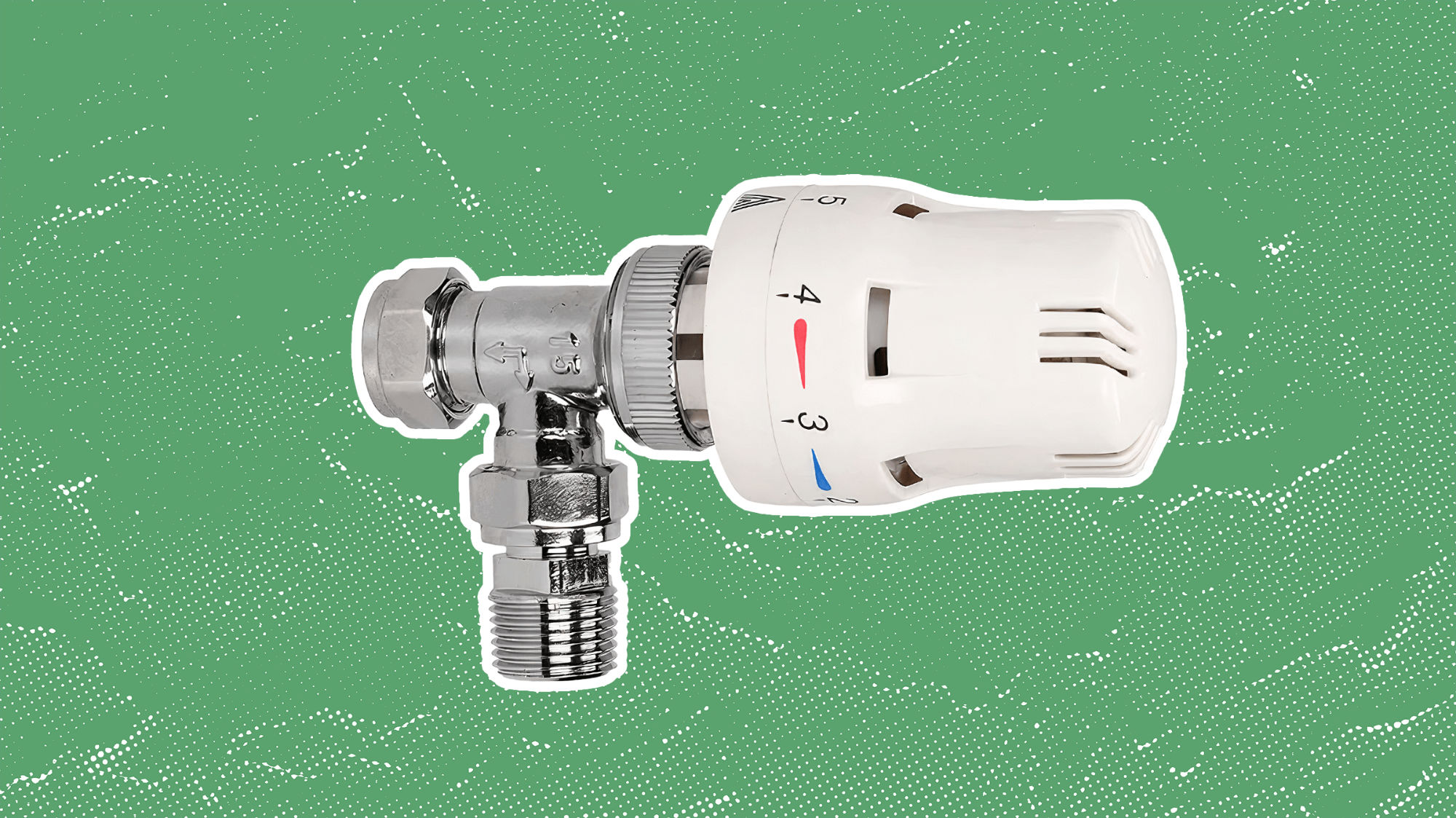

Check Radiator Valves

While bleeding your radiators can improve your heating system’s performance, sometimes the problem will be with your radiator valves.

Adjusting your radiator valves may cause them to heat up.

When it comes to the lockshield valve, it will likely require that you remove its plastic cover and use the right tool to alter the setting.

If you’re unsure about anything, we recommend checking the manufacturer’s manual.

As for the thermostatic valve, you can simply turn it to reach the ideal setting, although again, check the manual, if in any doubt.

If you’ve no success, you’ll need a heating engineer to replace your radiator valves if your boiler’s problem does, in fact, relate to these valves.

If you’re not sure, you’d need a qualified professional to identify the problem at this point either way.

Check the Condensate Pipe

Lastly, your boiler may shut down due to a frozen condensate pipe.

This can happen when temperatures are especially cold and, therefore, is most likely to happen in the winter.

However, it could theoretically happen at other times of the year, once temperatures drop enough.

If a condensate pipe freezes, water inside it will turn to ice resulting in a blockage. The result: your boiler will shut down.

Some signs of a frozen condensate pipe include:

Fault codes or warning lights on your boiler display. *

Gurgling or bubbling noises coming from the condensate pipe or boiler.

*You can check the meaning of these fault codes/warning lights with the manufacturer’s manual.

While it's generally best for a professional to thaw a frozen condensate pipe, it is possible for DIYers to undertake this fix if they have the right skills and knowledge.

You can that a frozen condensate pipe with one of the following solutions:

Pour hot (but non-boiling water) over the condensate pipe from a watering can. The reason it should be hot but not boiling water is that the latter can melt the plastic pipe and the watering can itself. So, while your first instinct may be to grab the kettle, you should instead use hot water, with a temperature of around 70°C to 90°C. Proceed with caution.

Place a hot water bottle, warm cloth, or even a microwavable heating pack around the part of the condensate pipe that is frozen.

Watch your feet in the process as ice that has formed on the outside of the pipe might begin to drip down along with any water, you’re using yourself.

Once you’ve taken one of the above steps, you may find you need to reset your boiler before it’s working again.

If it doesn’t happen automatically, reset your boiler per the manufacturer’s instructions.

Of course, if this doesn’t work despite noticing that your condensate pipe was frozen, it suggests that your boiler is suffering from an additional issue.

If you’re unsure of anything or can’t find a DIY solution that covers the DIY-suitable tasks discussed in this article, you should contact a Gas Safe Register engineer to find solutions.

Looking for a great deal on a new boiler?

If you’re aiming to get the best deal on a new boiler, consider getting a quote from us, here’s why:

Gas Safe installation within 24 hours.

Thousands of satisfied customers with an average score of 4.9 on Trustpilot, surpassing the market leader.

Which? Trusted Trader: Heatable is proudly recognised as a Which? Trusted Trader.

Price match guarantee: We will match any like-for-like cheaper quote.

Flexible payment options, including interest-free finance*.

Up to 12-year guarantee on selected boilers.

Fixed price guarantee: No hidden costs.

Save your quote and decide later.

Get an instant fixed price on a new boiler, here.

To learn more about boilers, visit our advice section, check out our YouTube channel, or read customer testimonials here.

Heat Happy.