Scholars aren't sure what a PCB is, but it could be a Particularly Costly Boiler fault. Rumour has it, it's a chip in your boiler that raids your wallet when broken.

The printed circuit board (PCB) in your boiler is essentially the control centre, where all the electronic components meet and receive their instructions, making sure all components sing in harmony, like ABBA.

A fault with the PCB is one of the major causes of emergency repair callouts, like if somebody murdered half of ABBA.

What is a boiler's PCB?

As mentioned, the PCB is like the brain of the boiler, where the electronic components meet and communicate, allowing them to work together in synchronicity to keep the boiler functioning as intended.

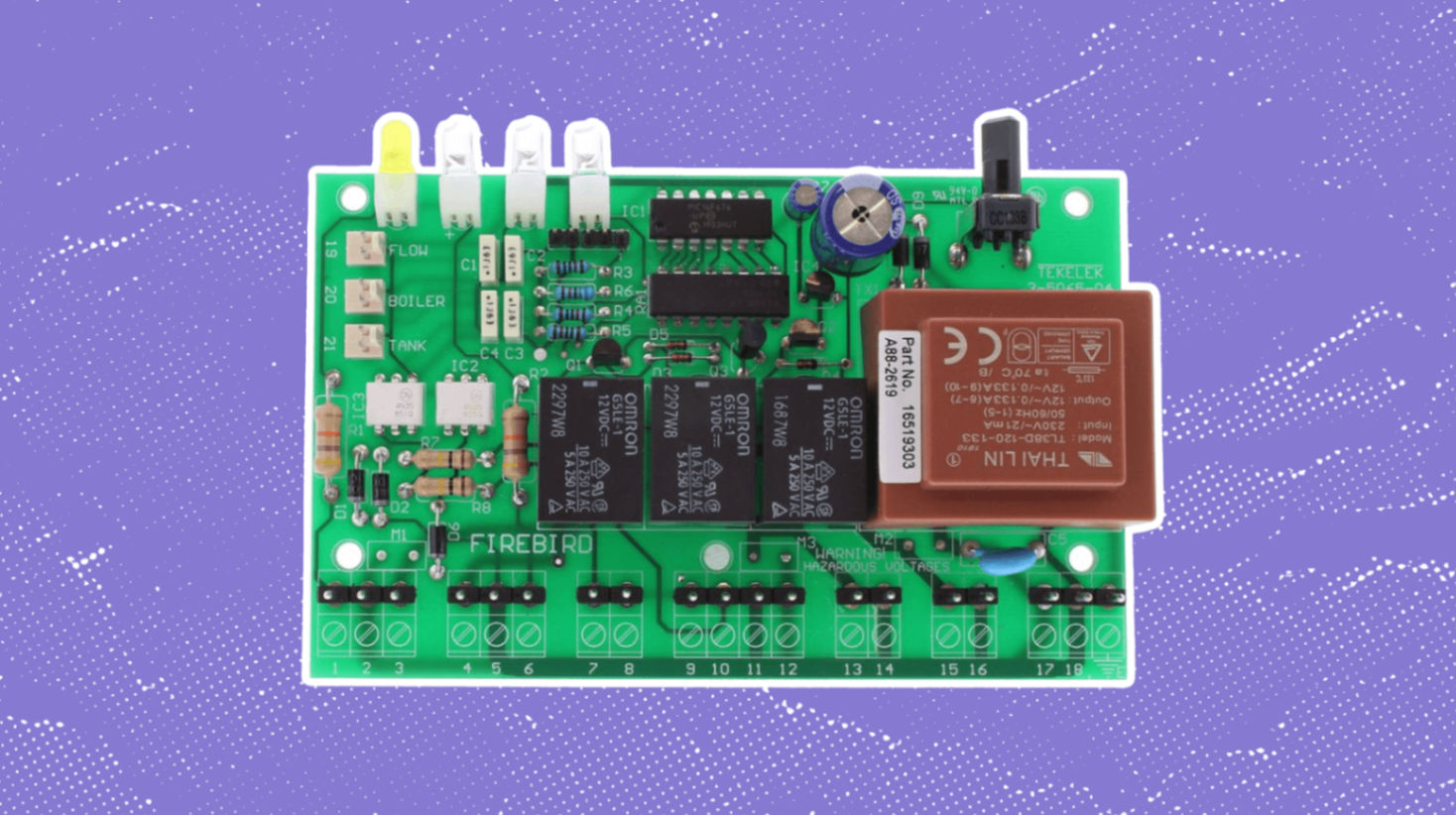

Here's what a PCB looks like:

For instance, a key safety mechanism is controlled by the PCB. Before the boiler ignites, the PCB will signal for the fan to start running, this is crucial since a change in air pressure is required for the harmful exhaust fumes to be extracted from the boiler during operation.

Once the fan is running (they rarely walk), the gas valve is enabled, allowing gas to flow into the burner where it is ignited so that combustion can take place, producing the heat.

The PCB essentially has negative feedback loops, this means that if any fault is detected e.g. a fan not working or a blocked condensate pipe, the boiler will stop working and display an error code.

This mechanism ensures damage to the boiler is limited and that safety is prioritised.

Curious to know which boiler brand performed worst? Find out in our report of the worst boilers.

Faulty PCB suspected, what now? 🕵🏻♂️

Well, to be clear, you should never open the boiler casing yourself or tamper with your boiler - it's dangerous.

If you suspect a problem, then you should always consult the help and advice of a registered Gas Safe engineer.

If your boiler is crazy old, then expensive repairs are increasingly likely. You should really consider installing a new boiler under warranty.

If your boiler will not work and is displaying an error code, it may be tempting to restart your boiler, but you really should not.

An error code is an indication that there is something wrong with your boiler, so you should not continue using it until the issue has been investigated and resolved.

Typically, a boiler will stop working and display an error code to mitigate the risks associated with either of the following:

To prevent damage to your boiler components e.g. the heat exchanger or pump.

To keep people in your property safe e.g. if there is a gas leak.

Not sure if you have a faulty PCB or something else? Check our list of the top 10 boiler problems common in all types of boilers.

Faulty Boiler PCB: Common Signs

Ultimately, issues with your boiler can be caused by a variety of different components, which is why it is important to get any error codes investigated by a qualified Gas Safe Engineer.

With that in mind, here are some of the most common signs of a faulty boiler PCB:

The display panel not working

If your boiler's interface is not lighting up or displaying anything, or if it is only intermittently displaying, this may be a sign of a loose connection between the PCB and the interface.

To diagnose this as the cause, a registered Gas Safe Engineer will need to open your boiler to investigate and check on the connection, making repairs if necessary.

However, bear in mind that some boiler manufacturers do have a setting that makes the interface flash if there’s a fault, so if this is the case it may not be an indication of loose wires causing an intermittent display.

Looking to pay for your new boiler monthly? Refer to our boilers on finance guide for more info.

Boiler gives off a burning smell

If you have noticed a burning smell coming from your boiler, combined with intermittent operation, and error codes related to electrical failures - run, fast.

No, but seriously, may have an internal leak inside your boiler resulting in a circuit board burnout.

Of course, water and electrics do not mix, so when they do (inside your boiler) you are going to experience issues.

...water and electrics do not mix

In order to determine if a burning smell is caused by a leak, a Gas Safe Engineer will need to open up the boiler and if it is caused by a leak, they will need to isolate and repair the leak as well as make any repairs to the PCB.

If the water damage is substantial, you can expect to pay for a complete boiler replacement - ouch.

Is your boiler making a lot of noise? Find out why in our noisy boiler guide.

No power to the PCB or display panel

If there is no power to your PCB at all, then you likely will not have any display on your interface and the boiler will not work at all.

Again, an engineer will need to open your boiler to determine this. If it has completely failed, you will likely need a new replacement PCB.

Even though it may be possible to attempt a repair, it often makes more financial sense to go straight for a replacement.

Boiler leaking or losing pressure? Use our quick and easy tool to get your fixed price boiler replacement.

PCB memory fault

If you discover an error code on your boiler display panel being a “memory fault”, then this is a sign that your PCB may need to be reconfigured.

Typically, this occurs in brand-new boiler installs, or, just after you have had your old PCB replaced with a new one.

If you have just installed a new boiler, refer to the user manual and look for the associated product code. You will need to enter this in order to synchronise the boiler with the PCB.

If you have replaced your PCB, then you could attempt the same fix, yet this is unlikely to be the cause since your engineer will have likely tested the boiler during installation.

Check our new boiler costs guide and use our boiler size calculator if you want to get a better understanding of how our fixed price boiler quote tool works.

PCB wiring issues

Since all key components of the boiler are wired up to the PCB, if there is a connection issue i.e. a loose wire between them, then components may no longer work.

The boiler is made with safety mechanisms in place, so if a certain component is no longer working it will stop operating completely until it is fixed.

For example, in the case of a fan that is not wired up to the PCB correctly, the boiler will turn off as the combustion process creates toxic exhaust fumes that need to be removed with the help of the fan.

Another example may be a disrupted connection between the gas valve and the PCB.

The gas valve will only open once it has received a signal from the PCB that the fan is running, therefore if these signals are not being communicated in sequence due to a wiring issue between the valve, the fan and/or the PCB the boiler will not operate.

Related boiler guides:

What causes a faulty PCB?

The biggest risk factor for developing a faulty PCB is the age of your boiler.

For example, combi boilers have lots of moving parts and after years of use wear and tear naturally takes its toll and boiler components can become damaged and dysfunctional.

Water damage and faulty PCB

As previously mentioned, water and electrics just do not mix, so if your boiler has a leak and that water ends up dripping onto your PCB it can very easily cause a burnout.

Typically leaks derive from the heat exchanger or the pump.

Why?

Just like all boiler components over time the wear and tear can result in irreversible damage, with the development of cracks and broken seals being two common culprits.

You may be interested in Gas Engineer Allen Hart explaining the most common boiler problems and how you can resolve them in the video below:

Boiler vibrations

Have you noticed your boiler vibrating more than usual before a suspected PCB fault developed?

A boiler that starts to vibrate can be a sign of an underlying issue that should be investigated, and since excessive vibrations can cause damage to components, they could be responsible for a PCB fault.

How much for a new PCB?

There is no escaping the fact that the PCB is usually the most expensive component in the boiler (similar to the heat exchanger). The exact cost depends on your boiler model and boiler manufacturer, but on average they are around £600.

Considering that most PCB failures result in older boilers that are way passed their warranty period, you must ask yourself if a replacement is worth it.

How long to to fix a PCB?

On average, replacing a boiler’s PCB will take a few hours to complete.

However, bear in mind that the engineer is unlikely to have your specific PCB model in stock, so you can expect to wait until they source it on your behalf.

Related heating guides:

Chips down? New boiler time. 🍟

You may need a new boiler.

You may need it fast, and with affordable monthly payments.

You may even need it from a company with top end local engineers, with 10,000 Trust Pilot reviews to back them up. Plus a Which? Trusted Trader award for good measure.

You may need a new boiler quote from us, Heatable 😘